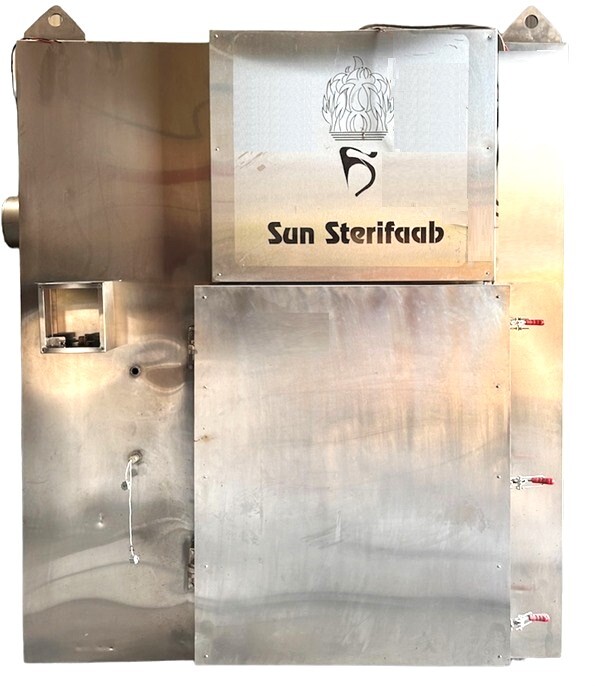

dry heat sterilizer

Product Details:

- Operate Method Automatic

- Usage Pharmaceutical sterilization

- Capacity 1700 Ltr

- Classification Sterilization

- Color Steel

- Product Type Dry Heat sterilizer

- Material SS316

- Click to view more

dry heat sterilizer Price And Quantity

- 2000000 INR/Number

- 01 Liter

dry heat sterilizer Product Specifications

- 1700 Ltr

- Sterilization

- Pharmaceutical sterilization

- Automatic

- SS316

- Dry Heat sterilizer

- Steel

- manual

- 900 x1200 x 1650 Millimeter (mm)

- 250-300 Celsius (oC)

- Pharmaceutical sterilization

- 1700 Ltrs

dry heat sterilizer Trade Information

- Cash on Delivery (COD) Cash Advance (CA)

- 2 Months

- Contact us for information regarding our sample policy

- wooden packaging

- Asia South America Africa

- All India

Product Description

DRY HEAT STERILIZER SPECIFICATIONS

1. MATERIAL OF CONSTRUCTION

1.1. Internal parts made from SS316 stainless steel.

1.2. Reinforced structure with 125mm glass wool & asbestos insulation for uniform air circulation.

1.3. Two doors (sterile and non-sterile sides) with hinge, toggle clamp, and food-grade silicon gasket to prevent leakage.

1.4. All components, including nuts, bolts, and sensors, made of SS316, with welded joints and curved edges.

2. FINISHING

External parts: 150 grit matt finish; internal parts: 220 grit mirror finish.

3. DOOR INTERLOCKING

Limit switches and indicating lamps activate if doors are open, with buzzer alerts on the opposite side.

4. AIR CIRCULATION

Dynamic balanced blower, made from stainless steel, with ISI motor. Ensures equal air distribution throughout the sterilizer.

5. HEATING

Air heated by 1 kW tubular SS316 heaters placed at the top, reaching temperatures of 250-300C, controlled via the control panel.

6. COOLING

HEPA-filter module cools air once sterilization cycle ends, automatically lowering temperature to room level.

7. PRESSURE MODULE

Pressure module with HEPA filter, activated during heating and cooling cycles to maintain positive pressure. Manometer provided for pressure monitoring.

8. EXHAUST

Motorized exhaust damper with heat-resistant gasket opens during the heating phase to expel moisture, then closes during sterilization and reopens during cooling.

9. SENSORS

Eight PT-100 sensors inside the sterilizer for precise temperature monitoring at various points.

10. AUTOMATIC CONTROL PANEL

- 3-phase, 415 V AC+/- 10%, 50 Hz input.

- Fabricated from SS304, with MIMIC diagram for status indication.

- Features include voltmeter, ammeter, microprocessor-based temperature controller, and LCD display.

- Supports 10 programmable recipes and a printer for printouts.

- Manual mode with two temperature controllers for pre-heating and sterilization.

11. TROLLEY AND CARRIAGE

Dimensions (mm):

- Internal Dimensions: 900 x 1650 x 1200

- Inlet Motor: 1 HP / 1440 RPM

- Exhaust Motor: 1 HP / 1440 RPM

- Circulation Motor: 5 HP / 1440 RPM

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Get a Quote

Get a Quote

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free